The only paving system 100% joint-free crack-free

At RCR, technological innovation is paramount to our commitment to excellence in industrial flooring. We have developed a unique technology that combines the best of two worlds: fiber reinforcement and post-tensioning. This combination allows us to maximize joint-free areas in our pavements, resulting in greater durability, strength, and performance efficiency. By integrating these two technologies, we can offer paving solutions that exceed expectations in terms of longevity and functionality. Our dedication to innovation drives us to continuously explore new ways to enhance our products and services, ensuring that our customers receive the most advanced and reliable flooring solutions on the market. With this unique technology, we are redefining industry standards and setting new performance levels in the field of industrial flooring.

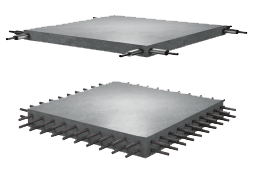

The SIGMASLAB® system utilizes post-tensioning technology in combination with steel fibers to maximize joint-free areas. The total elimination of joints enhances usability and allows for absolute flexibility in storage and traffic of all types of forklifts. It is the optimal solution for warehouses combining high traffic with high load demand.

Thanks to the significant contribution of post-tensioning with the SIGMASLAB® system, it's possible to design slabs with a high load capacity, potentially optimizing the floor thickness by up to 50% compared to the original design.

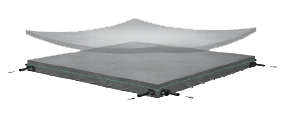

SIGMASLAB® enables the execution of traffic-defined aisles up to 100 meters in length without control joints, achieving high flatness (up to fmin 100). The absence of control joints ensures that the flatness achieved during floor execution is better preserved over time.

Through post-tensioning, the SIGMASLAB® system can physically counteract the phenomenon of curling, as the concrete is compressed by the tendons. The spacing of joints up to 100 x 100 meters minimizes the number of edges of the slab in the entire building.

The SIGMASLAB® system allows the manufacturing of slabs with an extremely high length-to-width ratio, facilitating their adaptation to any construction format.

RCR Industrial Flooring offers a comprehensive service, from design to application and maintenance of flooring, ensuring cohesive and high-quality solutions anywhere in the world. Our global network and collaboration among RCR companies guarantee an unparalleled experience for our clients.

To develop SIGMASLAB®, we immersed ourselves in an exhaustive study of the two individual systems that comprise it. This process allowed us to thoroughly understand the strengths and weaknesses of each, as well as their unique operation. We explored technical aspects, materials used, and construction methods to gain a comprehensive view of both systems. This deep knowledge provided us with the necessary foundation to merge these technologies into an innovative and effective solution: SIGMASLAB®.

The design and sizing phase is carried out by Monofloor consultants.

The calculations established by Monofloor define, based on the essential data collected from the site (platform quality, loads, environment, etc.), the thickness of the pavement, the correct dosage of LINK EVR®, and the metallic fibers using contractually recognized and experimentally validated methods.

After analyzing and evaluating the materials available in each geographical area, Monofloor engineers optimize and validate the concrete formula for each project through testing, according to the necessary adjustments (cement type, composition, additives, particle size distribution curves).

Monofloor also defines the specific reinforcement details, construction methods, concrete pouring phases, and control processes.

The SIGMASLAB® tensioning system is the result of the partnership between Bekaert, CCL, and RCR by combining post-tensioning wire with concrete reinforcement of Dramix® steel fibers.