At RCR, we drive excellence in industrial flooring with OPTIPAVE. This innovation combines reinforcement fibers and post-tensioning to create virtually joint-free surfaces, renowned for exceptional durability and performance. OPTIPAVE maximizes structural strength and pavement lifespan while reducing long-term maintenance costs. It adapts to high-demand industrial environments, such as logistics parks and heavy traffic zones. This system offers solutions beyond the conventional, raising the industry standard and setting new levels of performance. With OPTIPAVE, we are leading the way toward smart and sustainable pavements, driving success in industrial settings.

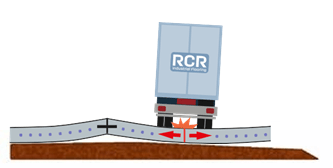

The position of sawn joints dividing the concrete slab in small panels is defined such as only one set of wheels can load one individual panel at any time. This results in a drastic reduction of stresses and tensions in the concrete. The volumetric stability of concrete is playing an important role and influencing the design as the curling effect already reduced by the size of panels is eliminated by the reduction of shrinkage.

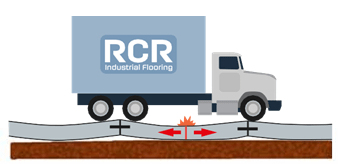

The adaptation of the slab conception with the dimensión of trucks and real requirements of logistic sector allows to eliminate most common problems of external slabs (fatigue cracks, deformation and pumping of adjacent panels…). These recuring pathologies induce high costs of repair and/or altered conditions of transit for vehicles.

Recurring problems in conventional external concrete pavements led us to look for more durable systems, more competitive and technically sound. OPTIPAVE®VRS system create a technological leap with its optimized distribution of loads and the use of latest technologies in concrete (SCC, FRC). The final result is a revolutionary system, with fast execution and optimized cost which solves problems due to fatigue, designs unfit to integrate intense traffic and execution mistakes.

OPTIPAVE®VRS significantly reduces warping at sawcut panel edges, enhancing durability against fatigue effects and load-induced stress. The system's design minimizes joint openings by shortening distances between sawn joints, bolstering load transfer and reducing the need for joint reinforcement. Furthermore, construction joints benefit from steel dowels, eliminating the necessity for joint sealing and reducing maintenance costs. With enhanced durability and reduced maintenance requirements, OPTIPAVE®VRS offers a reliable and cost-effective solution for industrial pavement projects.

Favorable load distribution in smaller panels generates less tensile stresses than usually considered in conventional pavements. Slab thickness will depend on the environment of the project, quality of subbase, weather conditions, type of vehicles and estimated traffic at mid and long term. In order to take into account all those parameters, a mechanistical dseign software has been developped OptiPave2 based on theory (FEM) and an extensive experimental study at Illinois Center of Transportation (USA).

LINK EVR®, beyond shrinkage and curling reduction is also preventing superficial micro- cracks (“crazing”) and seriously reduces concrete porosity, which is good for freeze-thaw behavior, to contain liquid spillage and to increase abrasion resistance

TCPavements®: The TCP method designs the dimension of the slab so that one set of wheels loads each one a any certain time, reducing the flexural stress and changing the failure mode. This results in a thinner slab for the same loading.

The calculation method of system OptiPave2 is aknowledged by ACI (American Concrete Institute) as a reliable approach to optimize concrete roads for intense traffic or transit areas for truck transit (ACI 330-2R-17).

The system has been already widely and successfully used with more than 10 000 000 m2 realized over ten years.

At RCR, innovation fuels our pursuit of excellence in industrial paving. Our pioneering OPTIPAVE system integrates fiber reinforcement and post-tensioning, resulting in expansive joint-free surfaces that excel in durability and performance. By uniting these advanced technologies, we deliver paving solutions that surpass conventional expectations, offering unparalleled longevity and functionality. With OPTIPAVE, we're not just raising the bar; we're redefining industry benchmarks and establishing new standards in industrial pavement performance.

Efficient and durable pavement solution for high-traffic logistics hubs.

Ideal for parking lots, offering strength and reliability for vehicles.

We care about the protection of your data. Read our Privacy Policy.